NEWS

Mayor Duke A. Bennett of Terre Haute, Indiana declares December 29th Walter Sommers Day on our founder's 100th birthday!

Mayor Duke A. Bennett of Terre Haute, Indiana declares December 29th Walter Sommers Day on our founder's 100th birthday!

Aguardian - the antimicrobial polyurethane.

Sommers awarded Compassionate Business by PETA in 2018.

Sommers awarded Compassionate Business by PETA in 2018.

POLYURETHANE

Polyurethane (PU or PUR) is one of the most versatile materials on the planet. Best known to the public in the form of flexible foam for earplugs, mattresses, packaging. It is an "organic polymer formed by reacting a polyol (an alcohol with more than two reactive hydroxyl groups per molecule) with a diisocynate or a polymeric isocyanate in the presence of suitable catalysts and additives." - Alliance of The Polyurethane Industry.

The chemistry of this novel polyisocyanate-polyaddition process was discovered in 1937 by Otto Bayer working for the Bayer Group (no relation to that family best known for aspirin, Alka-Seltzer and Flintstone vitamins). Bayer AG became part of IG Farben, a German chemical conglomerate who shamefully forced concentration camp, slave labor to produce Zyklon B used in the gas chambers of Auschwitz and other extermination camps.

The chemistry of this novel polyisocyanate-polyaddition process was discovered in 1937 by Otto Bayer working for the Bayer Group (no relation to that family best known for aspirin, Alka-Seltzer and Flintstone vitamins). Bayer AG became part of IG Farben, a German chemical conglomerate who shamefully forced concentration camp, slave labor to produce Zyklon B used in the gas chambers of Auschwitz and other extermination camps.

About the same time, on the other side of the Atlantic, Walter Sommers, a German-born, Jewish immigrant, began Sommers Fabrics in NYC, NY. He hired young Herman Schecter to help run his small business converting paper and textiles into imitation leather for fashion trades such as handbags, footwear, belts and leathergoods. "Plastics" were not yet manufactured for commercial use. In June of 1948, despite the progress of the company, Mr. Sommers wanted to leave NYC to raise his family in the Midwest. He took an executive position in a department store and decided to go out of his fledgling plastics business.

Walter Sommers made the decision to sell Sommers to Herman Schecter for a relatively small sum- $1,006.74. With wife, Doris, by his side, Herman utilized his dynamic personality to sell and develop new products. "Hy" Schecter was able to convince countless manufacturers of the advantages both in quality and economy of using plastics. He was so successful in marketing these products that large mills like the United States Rubber Company and General Tire made him their exclusive distributor of flexible, vinyl plastics. Decades later, organic chemistry advanced and these superior, coated fabrics became mainstream.

Sommers Plastics' polyurethane fabric is made in a process known as casting. Polyurethane resin, in prepolymer liquid form, is mixed with a curative and "cast" onto embossed release paper. There are hundreds of different release papers "RP" to choose from. Once the RP is covered with polyurethane resin it gets a secondary coating of polyurethane foam. This acts as a cushioning agent and an adhesive for the backing cloth. After going through multiple ovens half the length of a football field, the casting paper with polyurethane skin, foam and backing cloth wind around cooling rollers to be taken up at the end of the system in jumbo rolls. These rolls are cured in a heated room for 24-48 hours. After curing, the material goes to the inspection station where it is carefully examined before getting cut down to normal roll size for shipping to Sommers' customers and stock in Sommers' warehouse and distribution center in Clifton, NJ.

Quality polyurethane begins with petrochemical, prepolymer resins mixed with precisely color-matched pigments. A curative agent is blended into this master batch to begin the process. The choice of prepolymer resin, primarily diisocyanate or polyol, is determined by numerous factors depending on the end purpose of the material. Will the product be soft and leather-like or hard and durable offering more scuff resistance? Will the polyurethane be used for athletic footwear or applications requiring long-term hydrolysis protection such as contract upholstery for high traffic areas like airports, casinos, hotels, and places with 24/7 usage? Will there be a need to kill germs and have antimicrobial benefits (see AgUARDIAN®") What about competitive pricing? The questions about performance and price effectiveness determine which compounds are blended with the polyurethane resin- ether or ester. Each have advantages and disadvantages.

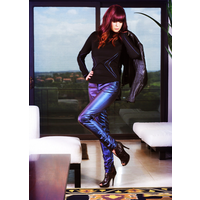

The PUR formula might include special additives and treatments- pearlized pigments, metallic flake, holographic glitter, or leather pull-up effect. Other ingredients can be added such as UV inhibitors for outdoor and marine use. There are options to add flame retardants, stain repellants or environmentally friendly, antimicrobial agents. Environmental awareness blankets every step of Sommers' process including saving water and energy as well as reduction and deodorization of volatile organic compounds.

Many tests are performed on the final material based on the market to which it is intended. No need for flame-retardant in athletic footwear but this is a big plus for upholstery. Is the polyurethane going to be used for seating in a healthcare environment? Antimicrobial agents are recommended. Sommers' proprietary silver-ion exchange formula, AgUARDIAN®, won NEOCON Gold and the "Nightingale Award for Advancement in Healthcare." AgUARDIAN® kills 99.9999% of microbes on contact.

Here is a comprehensive report of various testing methods conducted on coated fabrics compiled by the CFFA Chemical Fabrics and Film Association.

Unlike plastic fabrics made from polyvinyl chloride PVC or natural leather, polyurethane offers many advantages.

Sommers' Polyurethane Compared to PVC

• Less harmful to the environment. Contains no PVC, DOP, DOA and DDP which creates dioxin upon burning

• Contains no banned substances such as lead, Azo dyes, formaldehyde, heavy metals, latex, or plasticizer

• Easier breakdown after disposal

• Rich hand and feel with finer, high-resolution grain. Polyurethane can be tumbled to create natural leather grains

″ Waterproof, yet breathable

• Will not get stiff or brittle in cold

• Does not get soft and tacky in heat

• Excellent hydrolysis resistance

• Superior abrasion resistance and tear strength

Sommers' Polyurethane Compared to Rubber

• Abrasion, cut and tear resistance

• Oil Resistance, ozone resistance

• Harder durometer range

• Non-marking, non-staining

• High or low hysteresis

• Clarity or translucence

• Pourable or castable

• Microorganism resistant

Sommers' Polyurethane Compared to Natural Leather

• Animal-friendly and guilt-free. No animals killed or mistreated

• Natural leather requires toxic, heavy metals when tanning and tumbling

• Waste water from leather dye houses is highly toxic and contributes to water pollution

Sommers Plastics' expertise in creating fashionable, functional and fun polyurethane fabrics is unmatched. Some of the most spectacular polyurethane creations in the past decade were designed in the USA. These materials broke new ground going from original concept to final material and then into manufactured products.

• ChromaFlair® pigmented polyurethane features thin-film, light interference technology

• AgUARDIAN® polyurethane with Agion silver-ion antimicronial won "The Nightingale Award" for "Advancement in Healthcare," a first for a material of any kind. Sold for contract upholstery through distributors Maharam and C F Stinson. Learn more about AgUARDIAN®

Copyright 2011 Sommers Plastic Products. All Rights Reserved.

Copyright © 2012 Sommers Plastic Products, All Rights Reserved.