Details

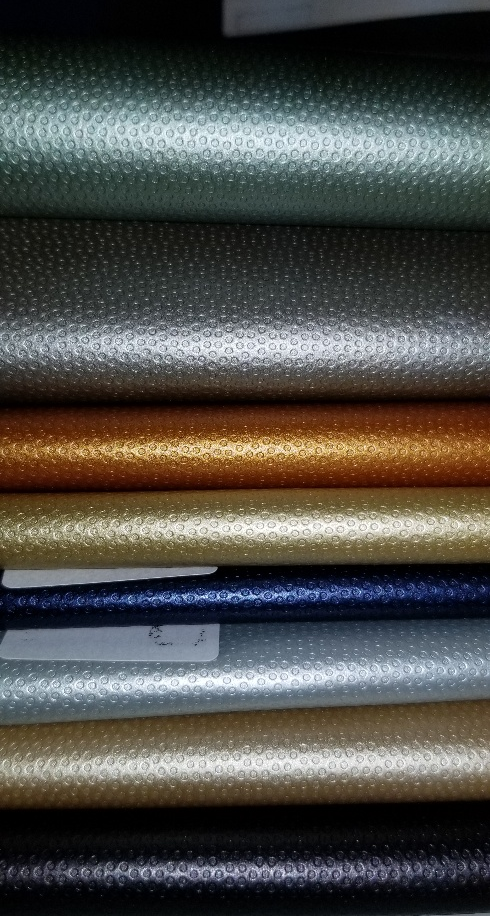

Rigid polycarbonate extruded 24" wide with deep moire embossing creating a dramatic, 3-dimensional effect. Sommers Plastics Lenticular in Rolls “LIR”

Material Description

Lenticular in Rolls “LIR” is a multi-lenses effect thermoplastic film manufactured of polycarbonate, flexible PVC and PETG. LIR gets its effects of motion and dimension from thousands of minute parabolic lenses that are molded into the surface on both sides of the film. These lenses create a pattern of absorption and reflection that are remarkable and unique. Shimmering silk, stardust sparkles; geometric repetition and three dimensional are some of the ways to describe LIR

Sommers’ materials also lend themselves to many downstream processing methods. Printability is the key to LIR applications. Silk screening, litho and flexo are just a few of the printing methods that have been successfully utilized on Sommers’ LIR. Polycarbonate and PETG can be easily hot stamped for rich and varied effects. LIR can also be easily die cut and adhesively bonded to many different substrates.

Applications

Applications for LIR are as varied as the imagination allows. It has been used in packaging, point-of-purchase displays, vending machines, clothing, apparel and accessories, business cards, decals, home furnishings, CD packaging, sporting goods and many other ingenious applications.

Material Form and Supply

Sommers’ LIR is available in both rolls and sheets. Material is produced at 25 3/8” wide (24” of useable surface guaranteed) and 0.015” think. Polycarbonate, flexible PVC and PETG are all available in roll form. Polycarbonate and PETG are all available in a standard sheet size of 25 3/8” x 54”. Custom sheet sizes are also available

Average Properties of Sommers’ LIR Polycarbonate

PHYSICAL TEST METHOD UNITS VALUES

Specific Gravity D-792 -- 1.20

Water Absorption D-570 % max 0.32 equilibrium

Rockwell Hardness D-785 (R-scale) 118

Pencil Hardness D-3363 Scratch Hardness B

Coef thermal expan D-696 in/in/oF 38 x 10-6

OPTICAL

Light Transmission D-1003 % 88-91

Refractive Index D-542 ND 1.586

Mechanical

Tensile Yield D-882 psi 8,700

Tensile Break D-882 psi 10,500

Elongation D-882 % 150

Tensile Modulus D-882 psi 350,000

Thermal

Tensile Heat Distort D-1637 oF 302@50psi

Deflection Temp D-648 oF 288@264psi

Vicat Soften temp D-1525 oF 305-315

Average Properties of Sommers’ LIR PETG

Physical TEST METHOD UNITS VALUES

Specific Gravity D-792 -- 1.27

Thermal Conductivty D-177 Btu•in/h•ft2•oF 1.50

Coeff Thermal Expns D-696 mm/mm•oC 5.1x10-5

Mechanical

Tensile Yield D-882 psi 7,500

Tensile Break D-882 psi 8,000

Elongation D-882 % 400

Tensile Modulus D-882 105psi 2.80

Thermal

Deflection Temp D-648 oF@264psi 147

Vicat Soften temp D-1525 oF 185

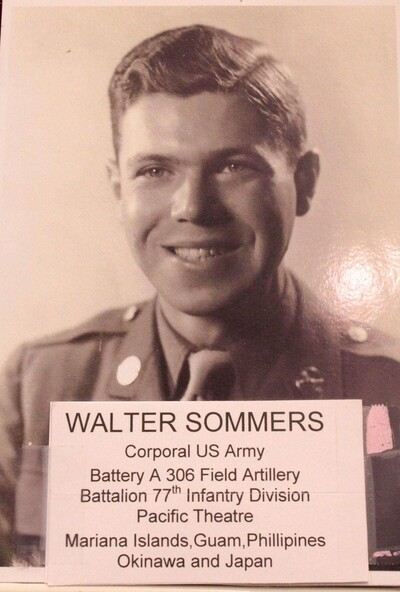

Mayor Duke A. Bennett of Terre Haute, Indiana declares December 29th

Mayor Duke A. Bennett of Terre Haute, Indiana declares December 29th